Imagine you’re trying to stick a sticker on a dusty, dirty surface. It won’t stick well, right? The same thing happens with garage floor coatings. Concrete preparation is like cleaning and roughing up that surface so the coating (the sticker in our metaphor) can stick properly.

Concrete surface profile (CSP) is how rough or smooth the concrete is. If it’s too smooth, the coating won’t stick. If it’s too rough, it can be too harsh. For your epoxy coating to stick, we need it just right; like sanding a piece of wood before painting it.

The Importance of Proper Concrete Prep for Garage Floors

States like Pennsylvania have pretty crazy, unpredictable weather conditions, and that can impact your concrete surfaces. Whether you’re a professional contractor or a homeowner looking to upgrade your garage floor, understanding the importance of CSP is crucial. This step ensures that the epoxy coating adheres correctly, providing a durable and long-lasting finish.

In-Depth Breakdown of Concrete Surface Profile (CSP)

Like we mentioned before, your concrete surface profile (CSP) refers to the texture of the concrete surface, which needs to be rough enough to allow the epoxy coating to bond effectively. According to the International Concrete Repair Institute, the roughness of concrete surfaces is ranked from CSP 1 (smoothest) to CSP 10 (roughest). For epoxy coatings to adhere properly, the concrete MUST have a CSP of at least 3. Methods such as low-pressure water jetting and acid etching typically produce CSPs below 2, which are insufficient for long-term bonding. These methods will get you a peeling garage floor, especially with a car going in and out or lots of foot traffic. On the other hand, aggressive techniques like sandblasting and rotomilling can create CSPs above 4, which are generally unnecessary for residential applications and can be too harsh on the concrete.

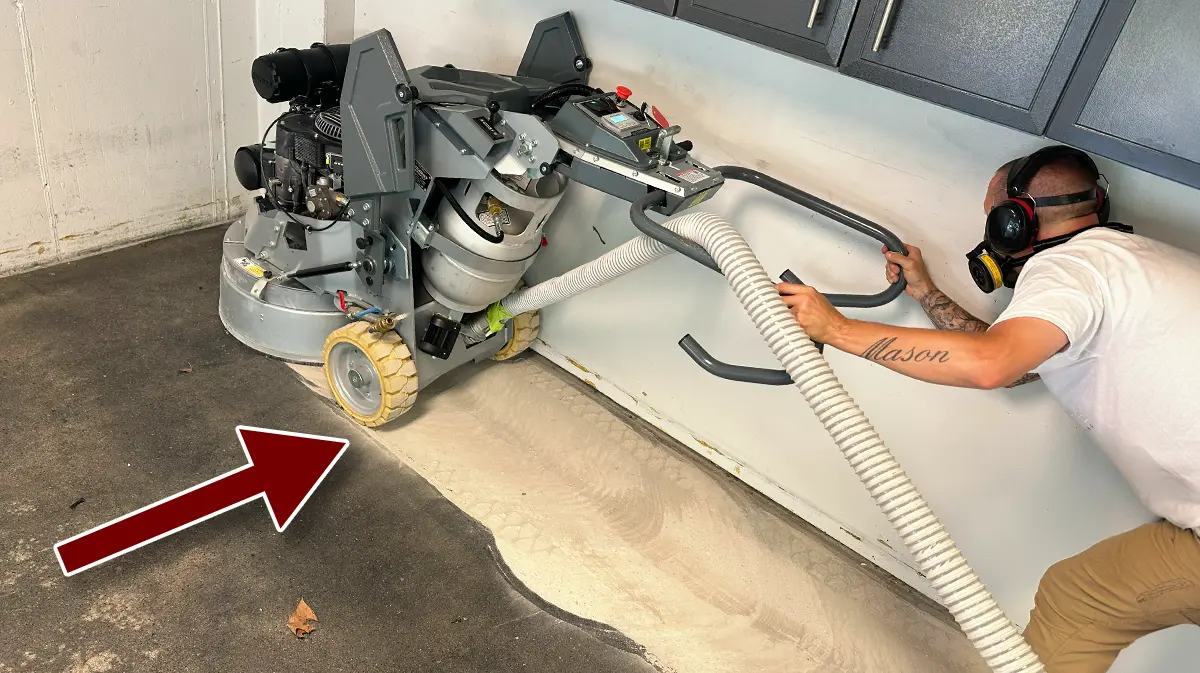

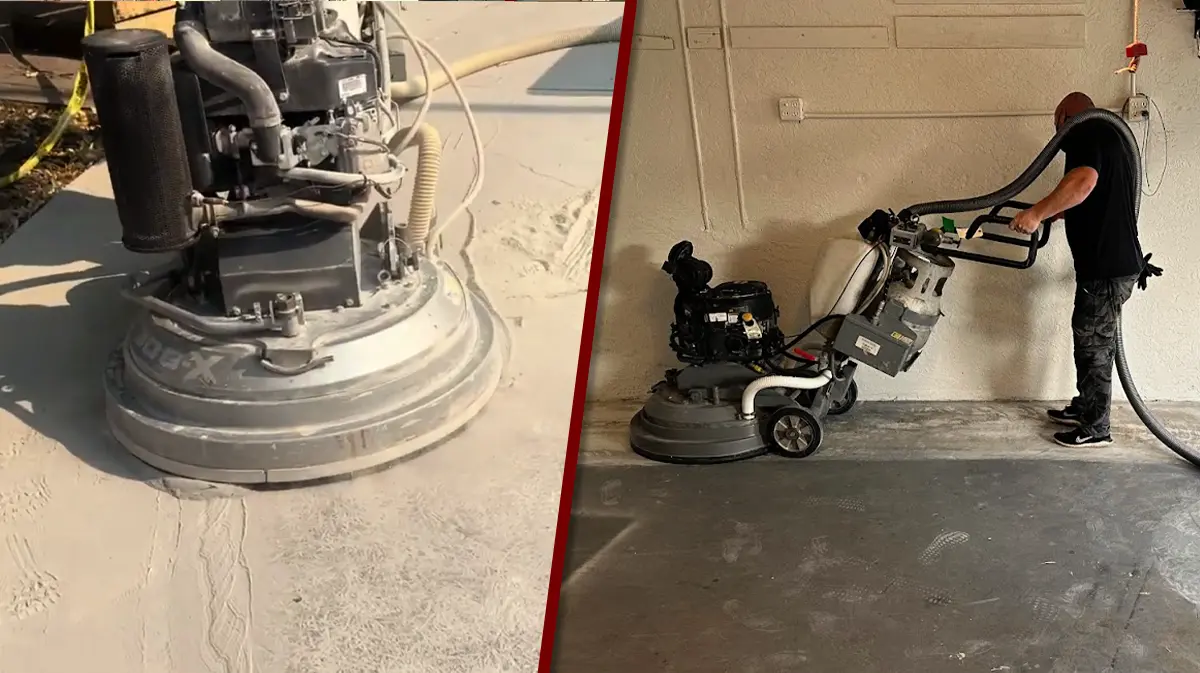

Achieving the Perfect CSP

The ideal method for achieving the perfect CSP for epoxy applications is grinding. Grinders can produce CSPs between 3 and 4, making them ideal for prepping concrete for epoxy coatings. However, the type of grinder used is also pretty important — propane grinders are way more powerful and efficient than electric grinders. Sure, they’re more expensive, but propane grinders reduce labor time and costs, making them a better investment in the long run. They’re also much safer, even in commercial environments, because they don’t require electricity, eliminating the risk of electrical hazards in wet or damp areas. They also produce near-zero exhaust emissions, making them suitable for indoor use.

Why Professional Installation Matters

DIY epoxy coating applications often wind up peeling because of inadequate concrete preparation. The equipment required to achieve the necessary CSP is usually too expensive and specialized for most DIYers. Professional contractors have the expertise and equipment needed to properly prepare the concrete, ensuring a high-quality, durable epoxy coating. This is Pennsylvania!

The weather can get just as hot and humid in the summers as it gets cold and snowy in the winters, so proper concrete preparation is vital for maintaining the integrity and appearance of epoxy-coated floors. Investing in professional services that use the right techniques and equipment will ensure that your garage floor withstands the test of time.