So, you’re thinking about giving your garage a fresh new look with a garage floor coating. But is DIY the right choice for your garage floor coating? This decision can make all the difference in how long your garage floor looks great and performs well. DIY kits vs. pro services — yes, we’re biased, but let’s dive into the details so you can understand why we’re so passionate about doing it right the first time.

DIY Garage Floor Coating: The Pros and Cons

- The Cost Factor

The main appeal of DIY epoxy flooring is the cost. DIY kits are cheaper upfront, and if you’re handy, it might feel like an easy weekend project. You can grab a kit at the hardware store, roll up your sleeves, and get to work—no scheduling with contractors or paying for labor. - Do It Yourself Factor

We’re in this business because we love to work with our hands to improve a space ourselves. For lack of a better term, it’s kind of a magical process. We understand the desire to want to build something yourself—just know that this process is more akin to roofing or installing custom doors, it’s not like hanging a new ceiling fan or throwing up a non-load bearing wall. - Preparation Isn’t as Simple as It Seems

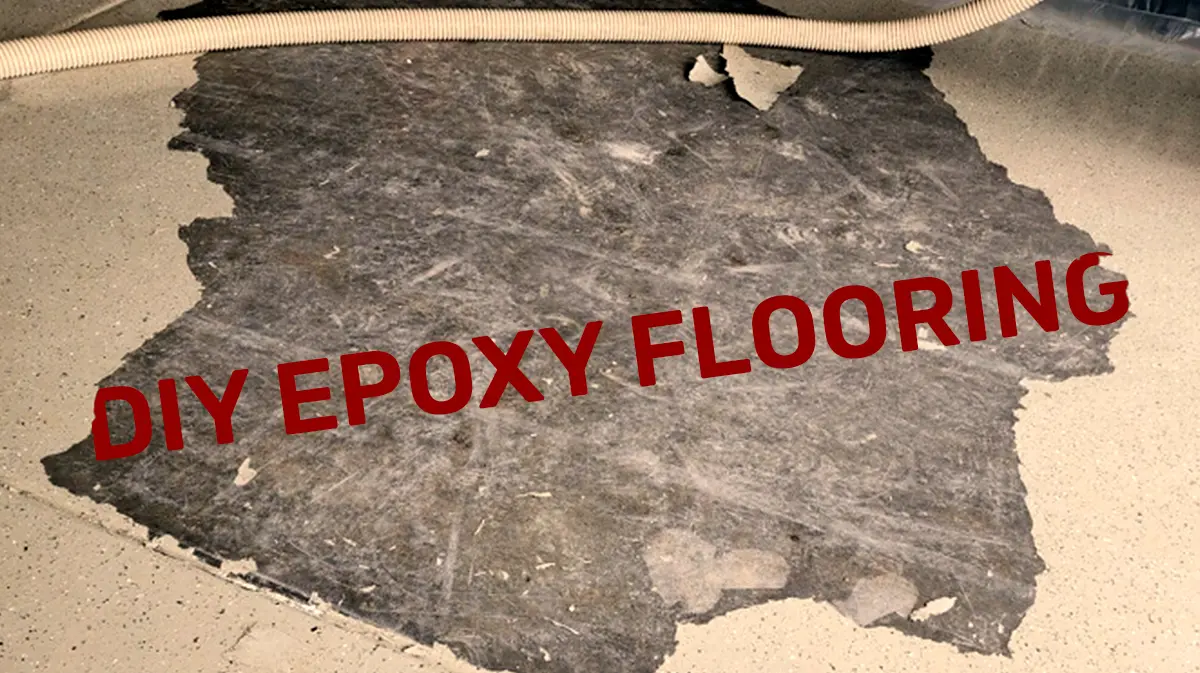

The catch lies in the concrete preparation (grinding and other prep steps to ensure your epoxy flooring actually sticks). Applying a garage floor coating is more than just slapping on some epoxy. It’s kind of like laying down other types of flooring inside your home—if the subfloor isn’t prepared correctly, you’re going to end up with serious issues down the road. In Pennsylvania, where the weather varies from cold winters to humid summers, concrete expands and contracts. A DIY kit usually recommends a basic acid etch, but this just doesn’t cut it if you want a durable coating that will last. Improper concrete prep leads to peeling, bubbling, and other issues that aren’t easy to fix. - Quality of Materials

Another drawback? The quality of DIY materials. Most DIY kits contain lower-quality epoxy that may look shiny at first but wears down quickly, especially under heavy use. (NOTE: We use an epoxy as our primer coat. However, we use a quality, 100%-solids moisture-mitigating epoxy; definitely not a low quality DIY epoxy), If your garage sees a lot of foot or vehicle traffic, DIY coatings might not provide the durability you need. They’re also prone to yellowing and scratching, which means your garage floor could start looking worse for wear sooner than you’d like.

Why Hiring a Professional Makes Sense

- Surface Preparation: The Key to Success

Professional installers take surface prep seriously, using industrial-grade grinders to make sure the concrete is ready for coating. This step is crucial for a proper bond, especially with the freeze-thaw cycles we get in Pennsylvania. Skipping this kind of prep is like trying to paint over a dirty wall—it might look okay for a minute, but problems are just waiting to surface. - High-Quality Products for Long-Term Results

Professionals use polyaspartic and polyurea coatings as the clear top coats (or color coats). They’re a huge “step up” from what you get in a DIY kit. These materials are designed for durability, UV resistance, and protection against the chemicals and salts that are common in a garage. Whether it’s resisting oil stains or standing up to Pennsylvania’s winter road salt, professional coatings have the upper hand. - Warranty and Peace of Mind

With a professional installation, you also get a warranty—something you just don’t get with a DIY project. If anything goes wrong, a professional team will come back and make it right. This peace of mind can be well worth the extra cost, knowing that you won’t be stuck redoing the whole project on your own dime.

The Bottom Line: What’s Right for You?

If you’re just looking for a quick, temporary fix and you’re not too worried about longevity for your garage floor epoxy, a DIY kit might work out okay. But if you want a garage floor that looks great, lasts for years, and can handle all that Pennsylvania’s weather throws at it, a professional GFC installation is the way to go. With the right prep, high-quality materials, and a solid warranty, it’s an investment that pays off in the long run.